Email: mason.c.kaufman@gmail.com Phone: 775-666-0706

Linkedin: www.linkedin.com/in/mckaufman

Mason Kaufman

Mechanical // Autonomous // Systems :: Engineer

Contact

Resume:

About Me

What Sets Me Apart

At the heart of my engineering approach is a passion for innovation, optimization, and a commitment to overcoming complex challenges with a unique blend of technical expertise, leadership, and a forward-thinking mindset. Whether I'm leading a team or developing a new design solution, my focus is always on exploring the potential, pushing boundaries, and turning seemingly impossible ideas into feasible, efficient realities. My experience in various demanding engineering projects has honed my abilities to collaborate, problem-solve, and adapt in dynamic environments, always with an eye on the bigger picture - the advancement of technology for the betterment of our world.

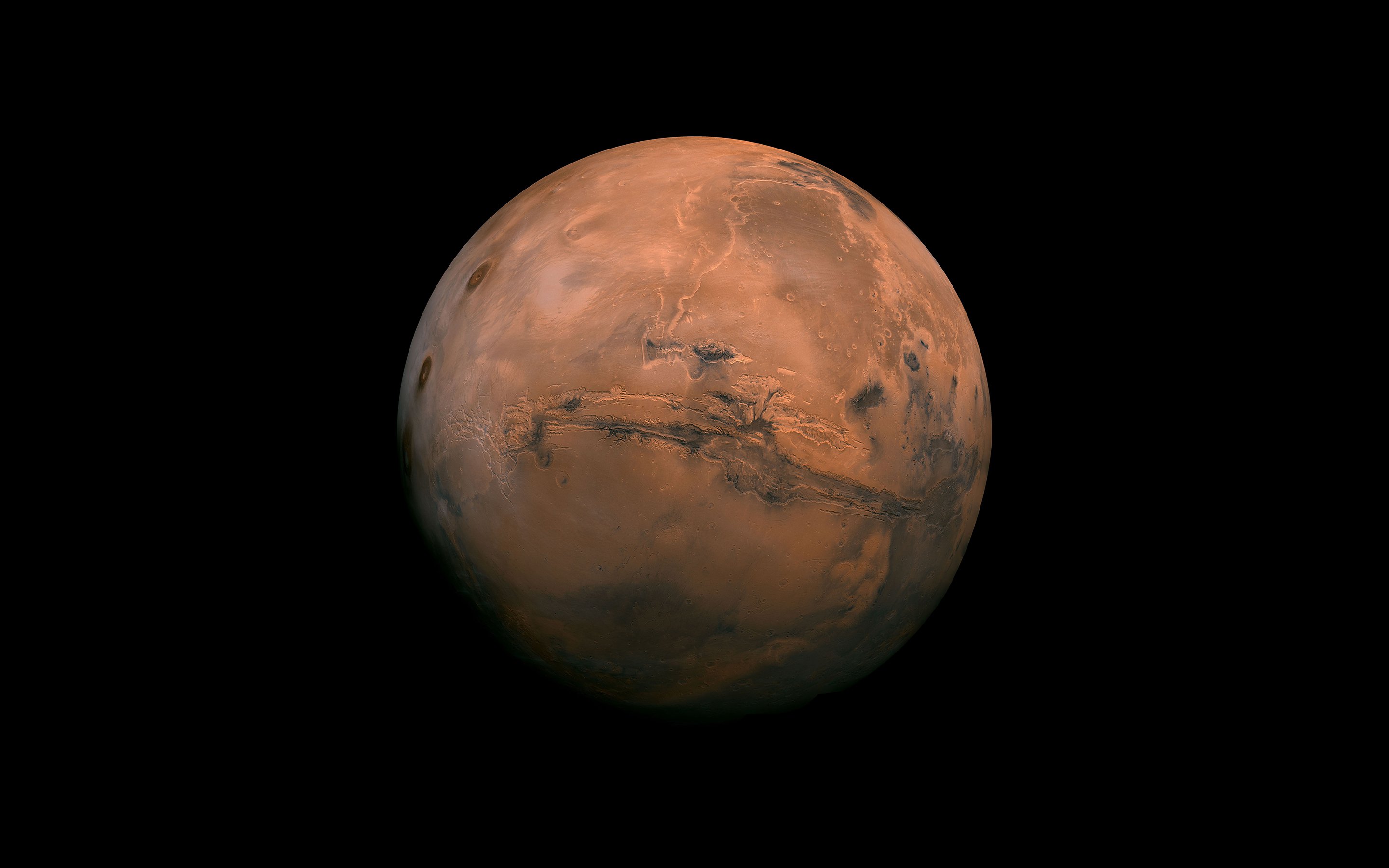

Nevada Electric Racing Team

Chief Engineer

As Chief Engineer of a new Formula SAE team, formed during COVID, I led my team through the countless design, manufacturing, integration, optimization and logistical hurdles in producing an 80 kW, 420v, electric race car for our first competition this June in Michigan.

-

Chassis Design: Achieved a significant 43% weight reduction in the initial chassis design, reducing the mass to 37kg while substantially improving torsional rigidity (~2.7 kN-m/deg confirmed experimentally). This contributed towards our overall weight goal of 220kg for the vehicle including the driver.

-

Aerodynamics: Designed an aerodynamic package capable of generating 530 N of downforce and 117 N of drag at 35 mph. The drag reduction system further reduced drag by 26% while retaining nearly 91% of downforce, thanks to rigorous optimization, CFD, and scale testing.

-

Suspension Optimization: Leveraged Matlab to create a multi-objective optimization program simulating kinematics and determining optimal suspension geometry.

-

Modular Vehicle Upright Platform: Pioneered design of a modular vehicle upright platform, enabling design flexibility for future iterations and saving over $7000 through significant redesigns permitting in-house machining of parts.

-

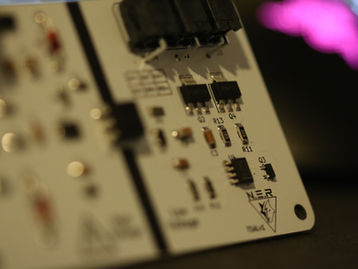

Thermal Monitoring Circuit: Developed a custom ESP32-based thermal monitoring circuit for our compact 693-cell battery enclosure. This ensured safe operation by using bit shifting to monitor 8 independent ADC chips through a multiplexer, communicating via CAN with the rest of the system.

-

Data Acquisition & Telemetry System: Integrated an advanced data acquisition and telemetry system for gathering valuable performance data during testing and competition, facilitating data-driven decision making for future optimizations.

-

Modular Drivetrain Mounting System: Incorporated a modular drivetrain mounting system to enhance rear assembly rigidity and simplify integration into future designs.

-

Vehicle Control Unit Firmware: Implemented custom firmware for the Vehicle Control Unit, taking into account various inputs to modulate power sent to the wheels. The inputs include steering angle, pedal travel, GPS data, inertial measurements, wheel speeds, motor RPM, torque, and comparison to a predictive algorithm.